Self unloading bulk carriers originated in the Great Lakes. The Conveyor System was installed into the Lakers size bulk carriers to deliver to ports with limited or no bulk-handling facility. These vessels transported material between the ports of the St. Lawrence Seaway and the Great Lakes; thus serving as an inland extension to the major ocean routes from Canada.

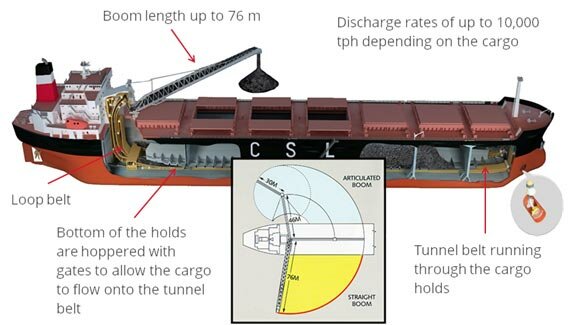

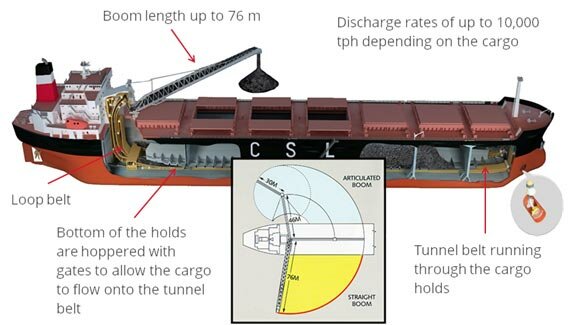

Fig: Self unloader components in operation

The conveyor system

The Conveyor System is the main distinguishing feature of the vessel. An essentially industrial type conveyor system and structure, designed for shipboard use, has given a specific identity to this type of bulk carrier generally called Self-Unloaders. In this design the ship holds terminate above the DB tank top forming a series of numerous open conical shapes called hoppers. These hopper openings are capped by hinged or sluice gates, which are operated hydraulically.

Fig:Self unloader on passage

The void space formed between the underside of these hoppers and the DB tank top along the length of the ship is called the tunnel. The conveyor belt runs in the tunnel along the ships length, and is fed by cargo through the gates. Gravity is utilised and the flow of cargo is controlled; governed by the load on the belt. The cargo is then lifted up vertically (loop or elevator lifts) or by gradual inclines and is transferred to the ships boom.

The boom is an extended structure with freedom of direction situated on the main deck, and encases the boom belt, for conveying the cargo to the shore terminal.

The concept of "gravity free-flow"

The Concept of Gravity Free-Flow is utilising the weight of the solid bulk cargoes to slide down through the gates onto the hold conveyor belt. The conveyors work as mechanical extensions, which transport the cargo horizontally and vertically. Some cargoes do not flow as well as others; and the sloping sides of the cargo holds are lined with UHMW sheeting, to encourage cargo flow, however on occasion certain cargoes may require to be assisted normally.

The SUL Bulk Carriers are not dependent on bulk-handling infrastructure on shore. The ships boom conveyor is able to discharge cargo to the shore i.e. it is the final stage in the transfer of the cargo leaving the ship and it can be positioned to discharge the cargo in most positions to a quay, to the ground, hopper, barge or other ship etc.

The SUL Straight Boom has freedom of movement in three directions up to the ships beam, and the Articulated Boom also aft of the beam. Some modifications to the boom (Short Boom) can be made to make it more flexible in nature. The Shuttle Boom has its limitations, and is used mainly for hopper discharge.

Self-Unloader technology

Many self-unloaders operate with a mix of high-tech and simple gravity. The cargo falls through controlled hydraulic gates onto conveyor belts located beneath the holds. The belts carry the cargo toward the stern of the ship where its transferred to an elevating system and lifted toward deck level. Once there, it is released onto the discharge boom, which is slewed to either port or starboard - up to 65 metres from the side of the ship, and then is off-loaded to the shore, either directly onto a stockpile or into a receiving facility.

The Hybrid Self-unloading vessels discharge using a mechanism, mostly cranes. They lift the cargo and discharge into hoppers on the deck. A series of conveyors mounted on the deck carry the cargo to the discharge boom, where the cargo is ultimately discharged to a single point on shore.

Deep sea self-unloading bulk carrier terminology

- Backstop : ratchet assembly, which allows a shaft to turn in one direction only.

- Beater wheel :(pocket elevator) positioned at the top of the system to assist in emptying of cargo from pockets.

- Belts :conveyors.

- Belt-Life :belt lifespan.

- Belt Scales :instruments used to measure cargo flow rate.

- Boom Structure : supporting conveyor belt, which discharges cargo to shore.

- Boom hub :pivot point of boom.

- Bucket elevator :belt belt with attached components forming buckets or pockets.

- Carriage wheels :wheels attached to belt tensioning carriage.

- Chute :steel structure, which directs cargo from one belt to another.

- Clips : products used for temporary repair of conveyors.

- Cold repair :repair carried out using rubber compound on surface of belt.

- Collomatic winch : hydraulic mooring winches in use, where applicable.

- Coupling grid :steel component used in Falk couplings as connection piece between the coupling halves.

- Crocodile clip :type of belt clip used on boom belt (where fitted) to shorten the boom belt when required for a Short Boom discharge.

- Cross-Conveyor :another term for a transfer conveyor.

- Deflector plate :steel assembly placed inside hoppers to direct fall of cargo from one belt to another.

- Deflection Pulley :a pulley which alters the alignment of the belt.

- Deflection wheel : (pocket elevator) type of pulley used on pocket elevator as a bend pulley. Dipping :unloading of a certain number of gates in a cargo hold in the early stages of a discharge.

- Discharge rate :flow rate of cargo during discharge.

- Draft gauges :remote instruments used to measure and display the drafts of a vessel.

- Draining :another term for clean out this is the latter stage of a discharge following dipping and main discharge, when all gates are unloaded.

- Drive pulley :a lagged pulley which is driven by a drivetrain, this pulley transmits the driving force to the belt.

- Emergency stop :switch providing the facility to shutdown the conveyor system when activated. These are placed at convenient locations on the ships main deck, at hatch coamings, in cargo control rooms at loop and in tunnel. These are also activated by pull-chords (see below).

- Falk coupling :a type of flexible coupling used on the drive pulleys.

- Flexco hinged fastener :a belt clip used in temporary belt repairs.

- Fluid drive :a coupling which is used to limit motor starting current.

- Gordon Scraper :trade name for the type of urethane belt cleaners in use on CSL vessels.

- Gooseneck hoppers : hopper located at the top of the elevator belts.

- Guide rolls : rollers to protect the belt from damaging itself against steel work or other abrasive surfaces; they do not touch the edge of the belt when running normally.

- Hang-ups :stacks of cargo which have not fallen through the gates as intended.

- Dead pulley :pulley situated at the discharge end of a conveyor belt.

- Hold conveyor belt :another term for tunnel belt.

- Hopper : a steel structure which contains and directs the flow of cargo from one belt to the next.

- Hog Back :inverted vee steel structure in cargo hold. Hot repair :vulcanisation. Hub :drive pulley. Idlers :rollers.

- Impact Idlers :lagged runner rollers usually located beneath a hopper.

- Impact plate :deflector plate or plate which absorbs force of cargo being discharged from a belt.

- Listometer lights :a set of five lights, two red, one white and two green which are controlled by a mercury switch. The white light, which is located in the centre of the set, illuminates when the vessel is upright. If the vessel takes a list of ½ degree, the inner red or green light will illuminate and the white light will be extinguished. If the vessel takes a further ½ degree list the second red or green light will illuminate. Red lights will indicate a list to port while green lights indicate a list to stbd.

- Load rate :rate at which cargo is loaded into the vessel.

- Loadicator :instrument which is used to calculate a load (or unload) plan for a vessel which will maintain the hull structure within safe stress limits.

- Loop belt : a type of elevator belt employing two belts which rotate in opposite directions.

- Lower bend pulley :bend pulley situated in the lower section of an elevator belt system whose function is to change the attitude of the belt.

- N.C.Feeder :non-consolidated system which uses a reciprocating motion and a series of openings to bring cargo down from a cargo hold onto a tunnel belt.

- Parking bolster : a support bracket attached to a boom at the designated point at which the boom can be safely supported whilst the vessel is at sea.

- Parking saddle :the support structure attached to the main deck onto which the parking bolster can be landed when the boom is stowed for sea.

- Pillow block :a bearing complete with mounting which has securing bolt holes cast into its base.

- Plough scraper :a scraper which is placed onto the return strand of a conveyor belt whose purpose is to deflect cargo material which may have fallen onto the return strand of the belt (usually vee formed). Pocket elevator belt a type of elevator belt which is fitted with cleats and side walls.

- Pull-chord :A length of small diameter wire (3 to 5 mm) which is strung along the sides of a conveyor belt. The lengths of wire are connected to switches, which stop the conveyor immediately in case of emergency. The number of switches depends upon the length of a conveyor belt. The switch has to be physically reset before the belt can again be restarted. Pull chord switches must be pulled before any maintenance work is carried out on a belt.

- Reducer : reduction gear box.

- Return idler :roller mounted beneath the return strand of a belt.

- Return roller :same as above.

- Rubber covered disc type idlers :reduce the impact of cargo being loaded onto the belt. The impact of cargo being loaded onto the belt is often the cause of severe cuts and gouges.

- Rubber lagging :is recommended for pulleys, to improve the co-efficient of friction, reduce slippage, and increase life of the pulley and belt. Grooving of the lagging has a cleaning effect on the belt, and breaks the film if moisture is present on the belt, to avoid slippage. The methods of fitting lagging onto pulleys varies, but vulcanising is generally used for shipboard pulleys.

-

- Saddle-piece :a piece of conveyor belt of usually 4 metres in length which can be used as an insert in the event of belt damage. Saddle-back inverted vee structure running fore and aft in a cargo hold, which acts as a flow divider between the gates to the tunnel belts.

- Scoop arm :a weighted lever, which is attached to the scoop of a Fluidrive coupling.

- Scraper :belt cleaner.

- Scraper bracket; :bracket supporting a belt cleaner.

- Scraper blades :hard wearing material which is in constant contact with a belt, used for removing material from a belt.

- Skirts :guides mounted at each side of a belt, which prevent cargo from being ejected.

- Skirt boards :are used in hoppers and chutes to guide/centre and settle the load on the belt as it leaves the point of loading. Their length is usually not less that 4 or 5 times the belt width.

- Snub :a pulley or an idler which is mounted close to a drive pulley, causes the belt to have increased circumferential contact with the drive pulley lagging.

- Speed switches :switched which detect a significant fall in belt speed whose function is to shut down the upstream belt to prevent a blockage of the system in the event of a belt stopping. or slowing down.

- Spillage :cargo which has spilled from the belts and remains on board on departure from an unloading port.

- Splice :the area at which a conveyor belt is bonded.

- Stub idler :an idler or roller, which is short in length and is mounted on a side bracket.

- Tail pulley drive :a tail pulley which is connected to drive trains.

- Tail pulley :large diameter pulley situated at the non-discharging end of a conveyor belt.

- Take-away rate :the rate (capacity) of a shore conveyor system.

- Take-up unit :hydraulic power pack for belt tensioning.

- Take-up sheaves :sheaves on the take-up unit, which allows adjustment of alignment.

- Take-up pulley :pulley on the take-up unit.

- Tank gauges : remote gauges displaying ballast tank surroundings.

- Tension (belt) belt :tensions to be set and maintained according to manufacturers instructions for optimum conveyor operations.

- Teledyne valve : hydraulic flow control valve used on gate controls to open or close a gate.

- Training the belt :effectively guiding the conveyor belt to run along the centreline by proper adjustment of carrying components and tensioning.

- Transfer belt :athwartship running belts used to change the direction of cargo travel and to feed the hopper for the elevating belt.

- Trash pump :centrifugal pump situated on the tunnel bilge used to pump out residues and slurry.

- Traffic lights :lights-red, amber and green in a vertical line, placed at frequent intervals along the side of hold conveyor belt. These lights indicate the load on the hold conveyor belt they serve. Red-overload. Amber- optimum load. Green-under capacity. The limits of the load are set on the cargo control panel in the CCR.

- Troughing idlers :used on the loop elevating system, to guide the edges of the sandwiched belts upwards and act as a seal.

- Tunnel : the fore and after space between the DB tank tops and the hold bottom hoppers, in which the hold conveyors run.

- Unbranded hot splice : vulcanised splice.

- Under-carriage : the carrying components of a conveyor belt e.g. rollers, frames etc.

- UHMW :the special low friction plastic lining attached on the sloping hopper sides in cargo holds to enhance cargo flow and prevent hang-ups. These are a series of sheets attached to the metal surface by studs and caps.

- Vibrator: a rotary unit containing hydraulically driven eccentric mechanism that creates vibrations and resonance. They are mounted on stiffeners on the hopper-sides in the tunnel, and at pre-determined intervals. They are used for bringing down cargo hang-ups, and the efficient cleaning out of gates.

Related information

-

Self unloader components

-

Function of loop & bucket belt elevators

-

Self unloaders various cargo handling gears

-

Various type boom conveyor belts - How the belt sytem practically works ?

-

Dealing with self unloaders stalled lift belt

-

Conveyor belt construction & troubleshoot guide

-

Conveyor belt installation guide

-

Conveyor belt repair & maintenence guide

-

Safe working practice onboard self unloading bulk carriers

-

Preventing conveyor belt fire onboard self unloading bulk carriers

-

Cargo work safety precautions

-

Various bulk cargoes - free flow ability

-

Various bulk cargoes & dealing with cargo hang ups

-

Navigation in Ice & safety precautions

-

Dust suppression procedure & environment protection

-

Preparations for cargo planning, handling & stowage

-

Maintaining safe stability onboard self-unloading bulk carriers

-

Procedure for bulk cargo handling prior to and during loading

-

Loading operations - voyage orders, draft restrictions, various grades and rates

-

Loading sequence and other related considerations

-

Preparations for discharging & related guideline

-

self-unloaders-discharging-operation

-

Safety precautions for boom operation

-

Directing gate operation, gate problems & crew duties

-

Cargo holds/ tunnels cleaning, maintenance and check items

-

Procedure for transporting coal on self- unloading bulk carriers

Our detail pages illustrated many safety aspects of Bulk carrier

Home page |||Bulk carrier types ||| Handling of bulk coal |||Cargo planning ||| Carriage of grain |||Risk of iron ores |||Self unloading bulk carriers |||Care of cargo & vessel |||Cargoes that may liquefy |||Suitability of ships |||Terminal guideline |||Hold cleaning |||Cargo cranes |||Ballast handling procedure |||Bulk carrier safety |||Fire fighting systems |||Bulk carrier General arrangement

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

It is vital to reduce the likelihood of over-stressing the ship's structure and also complying with all essential safety measures for a safe passage at sea. Our detail pages contain various bulk carrier related topics that might be useful for people working on board and those who working ashore in the terminal. For any remarks please Contact us

Copyright © 2010 bulkcarrierguide.com All rights reserved.

Although every effort have been taken to improve the accuracy of content provided the publisher of this website cannot take responsibility for errors. Disclaimer Privacy policy Home page