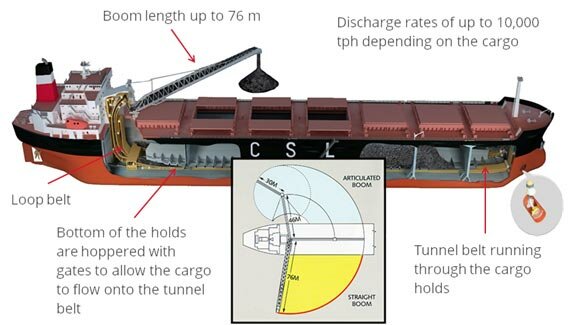

Fig:Self unloader discharging stone cargo

Fabric conveyor belt:

The carcase fabric is made of lengthwise yarns called warp and crosswire yarns called wefts. The warp yarns are tension bearing, while the weft yarns provide cross rigidity and impact tolerance. The warp and weft yarns are interwoven in many patterns: plain weave, straight warp weave, etc. with fillers and binders.

Multi-ply carcase:

Usually has three or more plies (layers) of interwoven fabric which are bonded together by elastic-polymer compounds. The number of plies (layers) determines the belts load ability and tensile strength. These types of fabric belts are of an older design, and have been phased out.

Reduced-ply carcase:

Uses weaves of high-strength synthetic fibres, nylon and polyester, which are formed into special fabric designs forming solid weaves of higher dimension, reducing the number of plies required. It incorporates thin layers of rubber between plies, or in the special weave design of its fabric.

Solid weave belts:

are formed from a single ply layer of fabric yarns, woven into a special design creating one solid weave, which is impregnated and covered with PVC. This type of belt requires relatively thinner covers and is more abrasion resistant.

Steel-cord conveyor belts:

are belts whose carcase is made of a single layer, of numerous parallel steel cables, embedded in rubber bonding. These steel cables forming the carcase are the belts tensile members. The belt construction is of three types:

- That which uses cables and rubber.

- That which is reinforced by transverse synthetic fabric cords and has one or more plies (layers).

- That which utilises transverse reinforcement including steel chords, or steel wires interwoven. This type of belting is used where operating tensions are high, extension of the belt is unacceptable, and the belt take-up has a limited travel area.

The life of the belt depends on:

- Proper training to prevent wear of edges.

- Avoiding contact with heat, oil or chemicals.

- Proper maintenance of its carrying components, with replacement of broken rollers, idlers etc.

- Avoiding objects other than cargo falling onto the belt, as these will tear or gouge the belt.

- Avoiding spillages, as these will fall between the belt and its carrying components, and cause damage. Carrying out inspections, edge repair and cold repair regularly.

- Adequate cover, and wetting of the belt when carrying out hot-work in its vicinity. The elasticity and elongation of the belts:

- Elastic stretch occurs during acceleration or deceleration.

Structural stretch is the elongation of the carcase when warp fabric stretches under load, and part of this stretch remains unrecoverable, resulting in an increase in the overall length of the belt. It is therefore necessary that good practices such as maintaining the correct operating tension, and gradual start-up without sudden shock loads, are carried out to increase the belt life.

The technical information supplied by the manufacturer must be referred to for the characteristics of the belts in use, and also to make a choice when ordering the belts. The following information is normally available:

- Dimensions.

- Rated tension.

- Ply separation length.

- Load and troughing parameters.

- Type of splice.

- Gauge of covers.

- Pulley radii.

- Cleaning recommendations.

Deck conveypr belt

Deck conveyor system discharges bulk material by using deck cranes that load the cargo into hoppers located on deck. From the hoppers the cargo is fed onto longitudinal belt conveyors and transferred to a cross conveyor which discharges via a boom conveyor into the shore receiving facilities.

Depending on the number of cranes and hoppers, a peak capacity of 4,000t/h can be reached and an average discharge rate of 1,000-2,500t/h can be maintained. This rate is mainly dependent on the cranes, which may have to be upgraded to provide the best possible discharge rates.

Related information

Cargo holds bulk flow gate, basket gate & non - consolidated feeder

Our detail pages illustrated many safety aspects of Bulk carrier

Home page |||Bulk carrier types ||| Handling of bulk coal |||Cargo planning ||| Carriage of grain |||Risk of iron ores |||Self unloading bulk carriers |||Care of cargo & vessel |||Cargoes that may liquefy |||Suitability of ships |||Terminal guideline |||Hold cleaning |||Cargo cranes |||Ballast handling procedure |||Bulk carrier safety |||Fire fighting systems |||Bulk carrier General arrangement

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

It is vital to reduce the likelihood of over-stressing the ship's structure and also complying with all essential safety measures for a safe passage at sea. Our detail pages contain various bulk carrier related topics that might be useful for people working on board and those who working ashore in the terminal. For any remarks please Contact us

Copyright © 2010 bulkcarrierguide.com All rights reserved.

Although every effort have been taken to improve the accuracy of content provided the publisher of this website cannot take responsibility for errors. Disclaimer Privacy policy Home page