Home ||| Bulk Cargo ||| Planning ||| Care ||| Safety||| Self unloaders

Fixed CO2 & HALON Installation for cargo ships

CO2 room A fully-separated space designed and equipped for the storage of CO2 cylinders. CO2 room shall be located aft off the collision bulkhead. As far as possible, the CO2 room should be located on the open deck. If such arrangement is not possible, the room can be located one deck below the open deck and shall have a stairway or ladder leading directly to the open deck. Access doors must open outwards.

The use of fixed installations must be carefully considered at an early stage especially in the case of a cargo ships engine room fire. In particular Carbon Dioxide/Halons are to be used before there is a build up of temperature causing severe convection.

In the case of a serious fire, to effectively use CO2/Halons, the time factor is probably in the order of 10-12 minutes from the time that the fire situation is deemed to be beyond the capability of first aid fire fighting equipment. Proper closing down of the space is essential before the system is operated, and therefore the Chief Engineer Officer must make the necessary preparations during the first aid fire fighting stage in accordance with the vessels Ventilation Shut-down Plan.

In the majority of the ships the fixed fire extinguishing system to the Engine Room is CO2/Halons. This is a "once off" shot and to have maximum effect all ventilation fans must be stopped and the fire flaps closed. Several minutes may be required before all necessary preparations have been completed and the CO2/Halons can be released.

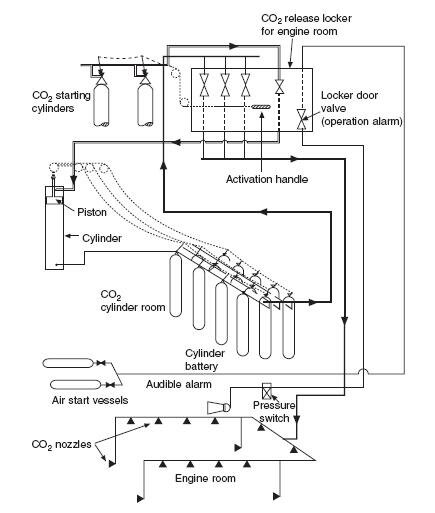

Fig:CO2 total flooding system

As total loss of power may result from flooding the Engine Room with CO2/Halons the Chief Engineer Officer must consult with the Master before releasing the CO2/Halons.

Once this course of action is decided upon the Senior Officer in charge of the Emergency Party must act to release the CO2/Halons.

Prior to the release of any fixed gas based extinguishing medium in an enclosed space, and to ensure that no personnel are present in that space positive verification is to be made by mustering all the vessels crew.

After flooding with the extinguishing gas, a careful watch is to be made on the space temperature. On no account is the space to be ventilated or opened up until the temperature has fallen to a safe level. Failure to do this will result in the fire restarting with no further means to control or extinguish it. Regardless of system fitted onboard, a description of the system is to be included within the shipspecific Fire Training Manual.

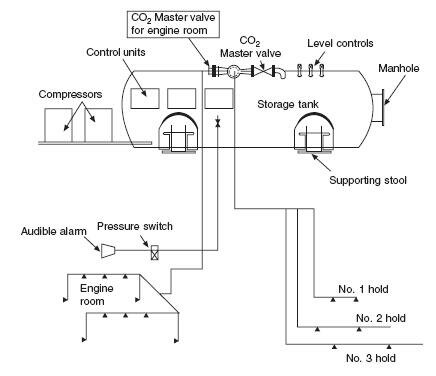

Fig:CO2 total flooding system for engine room

Precautions Using Fixed C02 Systems

Once the system has been fully released and the fire extinguished, no personnel are to enter the space until the main supply valve has been shut. The space must of course be well ventilated prior to entry in order to remove all traces of CO2 and ensure sufficient air has been introduced to make the space safe. It can take a considerable amount of time for the fire to be completely extinguished and for the space to cool down. (in excess of 24 hours). Procedures for entry into enclosed spaces are to be followed in such cases.

Halons 1301

Unlike CO2, Halons 1301 does not smother a fire. Instead it interferes with the combustion cycle that occurs in a fire, arresting the heat producing reactions.

Whilst Halons is not toxic at normal temperatures at temperatures above 800C toxic vapours may be given off. Therefore personnel must immediately evacuate a space where Halons has been released into.

There are some environmental concerns over the use of Halons and as a result this type of fire-fighting medium is being phased out.

Maintenance of Carbon Dioxide and Halons Systems

The onboard planned maintenance system should include all maintenance requirements of the fixed fire fighting system as outlined by the system manufacturers and the flag administration including:

- Maintenance and inspection procedures and instructions;

- Required schedules for periodic maintenance and inspections;

- Listing of recommended spare parts; and

- Records of inspections and maintenance, including corrective actions taken to maintain the system in operable condition.

The PMP should clearly indicate which parts of the recommended inspections and maintenance schedule should be completed by competent trained personnel. Whenever fixed fire-extinguishing systems are subjected to inspection or maintenance, care must be taken that the system is not accidentally triggered off. Prior to performing any work, a risk assessment should be developed .

Extreme care is also to be taken when inspecting the room where the extinguishing medium is stored. Ventilation must be continuously running to eliminate any chances of asphyxiation which may result from CO2 leaks.

In addition to the recommendations of the manufacturers, and in accordance with IMO MSC.1/Circ.1318, the following items should be included within the PMS.

Monthly Inspections: CO2 / Halons alarms are to be tested monthly. Note, where CO2 / Halons alarms automatically shut down ventilation and machinery on opening of control boxes, appropriate precautions are to be taken to avoid shut down of machinery. Such tests shall be made only with the Chief Engineers approval after consultation with the Master.

At least every 30 days a general visual inspection should be made of the overall system condition for obvious signs of damage, and should include verification that:

- all stop valves are in the closed position;

- all release controls are in the proper position and readily accessible for immediate use;

- all discharge piping and pneumatic tubing is intact and has not been damaged;

- all high pressure cylinders are in place and properly secured; and

- the alarm devices are in place and do not appear damaged.

In addition, on low pressure systems, the inspections should verify that:

- the pressure gauge is reading in the normal range;

- the liquid level indicator is reading within the proper level;

- the manually operated storage tank main service valve is secure din the open position; and

- the vapour supply line valve is secured in the open position.

Annual Inspections: The boundaries of the protected space should be visually inspected to confirm that no modifications have been made to the enclosure that have created uncloseable openings that would render the system ineffective.

All storage containers should be visually inspected for any signs of damage, rust or loose mounting hardware. Cylinders that are leaking, corroded, dented or bulging should be hydrostatically retested or replaced.

System piping should be visually inspected to check for damage, loose supports and corrosion. Nozzles should be inspected to ensure they have not been obstructed by the storage of spare parts or a new installation of structure or machinery.

The manifold should be inspected to verify that all flexible discharge hoses and fittings are properly tightened.

All entrance doors to the protected space should close properly and should have warning signs, which indicate that the space is protected by a fixed carbon dioxide system and that personnel should evacuate immediately if the alarms sound. All remote releasing controls should be checked for clear operating instructions and indication as to the space served.

The bottle levels are also to be tested on an annual basis by ships staff using the testing equipment supplied.

Inspections at each intermediate, periodical or renewal survey: All high pressure cylinders and pilot cylinders should be weighed or have their contents verified by other reliable means to confirm that the available charge in each is above 905 of the nominal charge. Cylinders containing less than 90% of the nominal charge should be refilled. The liquid level of low pressure storage tanks should be checked to verify that the required amount of carbon dioxide to protect the largest hazard is available.

The hydrostatic test date of all storage containers should be checked. High pressure cylinders should be subjected to periodical tests at intervals not exceeding 10 years. At the 10-year inspection, at least 10% of the total number provided should be subjected to an internal inspection and hydrostatic test. If one or more cylinders fail, a total of 50% of the onboard cylinders should be tested. If further cylinders fail, all cylinders should be tested. Flexible hoses should be replaced at the intervals recommended by the manufacturer and not exceeding every 10 years.

The discharge piping and nozzles should be tested to verify that they are no blocked. The test should be performed by isolating the discharge piping from the system and flowing dry air or nitrogen from test cylinders or suitable means through the piping.

Halons initiators must be replaced by a service engineer every three years. Inspections at Each Renewal Survey by a Competent Authority

Where possible, all activating heads should be removed from the cylinder valves and tested for correct functioning by applying full working pressure through the pilot lines. In cases where this is not possible, pilot lines should be disconnected from the cylinder valves and blanked off or connected together and tested with full working pressure from the release station and checked for leakage. In both cases, this should be carried out from one or more release stations when installed. If manual pull cables operate the remote release controls, they should be checked to verify the cables and corner pulleys are in good condition and freely move and do not require an excessive amount of travel to activate the system.

All cable components should be cleaned and adjusted as necessary and the cable connectors should be properly tightened. If the remote release controls are operated by pneumatic pressure, the tubing should be checked for leakage and the proper charge of the remote releasing station pilot gas cylinders should be verified. All controls and warning devices should function normally and the time ideally, if fitted, should prevent the discharge of gas for the required time period.

After completion of the work, the system should be returned to service. All releasing controls should be verified in the proper position and connected to the correct control valves. All pressure switch interlocks should be rest and returned to service. All stop valves should be in the closed position. Masters are to refer to the regulations laid down by the Flag Administration / Class for the requirements to hydraulically pressure test gas cylinders of fixed systems.

Fixed Dry Powder System

Fixed Dry Powder systems are to be checked monthly to ensure that valves are set correctly, guns operate freely and nitrogen bottles are at the correct pressure. Every four months all pipe work is to be blown through with compressed air.

Related articles

Required Personal protective equipment (PPE) for working in a confined space

Ships Confined area safe practice

Shipboard hazards & bulk carriers safety guideline

Health hazards for personnel working in a dusty condition onboard

Related articles

- Fire, fire fighting & fire fighting equipment

- Fire in cargo holds & emergency preparedness

- Fire fighting equipment for seagoing bulk carriers

- Fixed CO2 & HALON Installation for cargo ships

- Smoking regulations for ships carrying dangerous goods

Our detail pages illustrated many safety aspects of Bulk carrier

Home page |||Bulk carrier types ||| Handling of bulk coal |||Cargo planning ||| Carriage of grain |||Risk of iron ores |||Self unloading bulk carriers |||Care of cargo & vessel |||Cargoes that may liquefy |||Suitability of ships |||Terminal guideline |||Hold cleaning |||Cargo cranes |||Ballast handling procedure |||Bulk carrier safety |||Fire fighting systems |||Bulk carrier General arrangement

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

It is vital to reduce the likelihood of over-stressing the ship's structure and also complying with all essential safety measures for a safe passage at sea. Our detail pages contain various bulk carrier related topics that might be useful for people working on board and those who working ashore in the terminal. For any remarks please Contact us

Copyright © 2010 bulkcarrierguide.com All rights reserved.

Although every effort have been taken to improve the accuracy of content provided the publisher of this website cannot take responsibility for errors. Disclaimer Privacy policy Home page