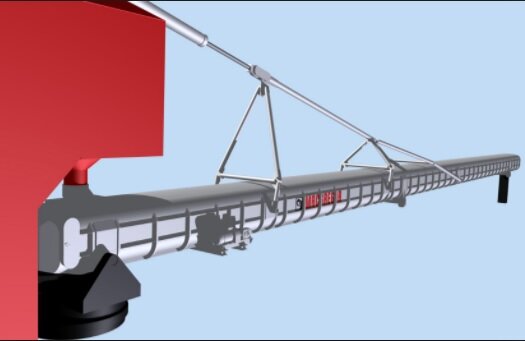

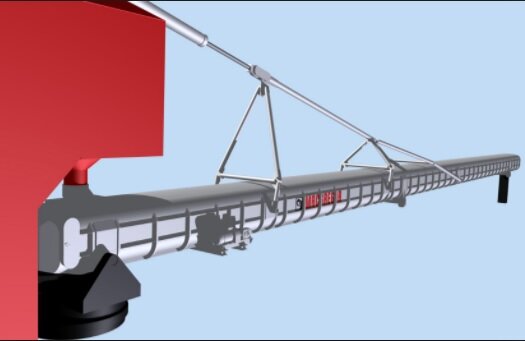

The boom belt, generally referred to as the boom, is the point at which the cargo is discharged from the vessel. The boom is a long steel structure that has freedom of movement in two directions, and is mounted on the main deck, or in a casing on the stern.

The conveyor belt runs on a carriage along the boom. Adaptations are sometimes made to its structure to suit the discharge facilities in the vessels trading area.

Boom conveyors have been equipped with conveyor covers, water spray nozzles and dust collectors to reduce spillage and keep dust emissions to a minimum. The smooth upper surface is designed to prevent ice formation and the inner bottom surface is also smooth to facilitate cleaning. Service and inspection are catered for by walkways alongside the belt. A longer life span is anticipated because the components are protected against the external elements.

Fig:Boom operation self unloader American Fortitude

Some old designs have the boom fitted just aft of the forecastle, and running aft. At the head of the boom is a hood which houses an adjustable deflector plate which directs the flow of cargo. There is also a water-spray arrangement provided which is used on certain dusty cargoes to protect the environment.

It is important to check that the nozzles of the water-spray are not clogged. After parking the boom, it is important to ensure that the link-plate is lowered by extending the piston of the luffing cylinder, to allow for the vessels longitudinal flexing in a seaway. Where the boom is hoisted and slewed by wire and tackle, the strain of the wires must be eased-off on tightening as the difference in atmospheric temperatures could have an adverse effect.

The articulated boom

This is a design with increased freedom of movement. It is articulated or flexibly-jointed at the centre, dividing the boom in two. The articulation allows multi positioning of the boom head, and thus improved flexibility.

The horizontal limit of the boom head is 45 degrees aft of the beam. The diagram of sweep, and the limits of the inner and outer booms in both planes are available in the manufacturers manual. The outer boom can be used with the inner boom still on the parking-cradle, however, all tie-downs must be removed. After parking the boom it is important to ensure that the link-plate is lowered, by extending the piston of the luffing cylinder, to allow for the vessels longitudinal flexing in a seaway.

The shuttle boom

This type of boom is housed on the stern, and is designed to suit the specifications of shore hoppers in specific trading area. It is extended from a hydraulic door at the side by a shuttle arrangement.

When securing for sea, it is important to ensure that the shuttle boom locking and tie-downs are engaged, and that the hydraulic door is shut and locked. During rolling, an unlocked boom could force the shuttle door open, allowing water-ingress. A shuttle door indicator light is fitted on the bridge however a visual check and report that the door is closed, is essential.

The short boom

This is a modification carried out to the straight boom, to enable discharging in certain ports in the trading area.

How the belt system works

The belt systems are started sequentially, the boom belt first, followed by the elevating belt, the transfer belts and then lastly the tunnel or hold belts. Unloading is to be carried out in the AUTOMATIC MODE ONLY. It is possible to run the unloading system manually but this is only for maintenance purposes. Unloading with the belt system set in the manual mode bypasses all speed sensing switches, and leaves the system open to being plugged if a belt should stop.

All the Start-Up Alarms will sound in advance on auto giving caution. All alarms in the system are to be checked and maintained in good working order. The pocket elevating belt is controlled by computer controlled automation, which has set programmes of sequential stages and speeds to suit the characteristics of the cargo being discharged. The stopping sequence will be in the exact reverse order.

Related information

Cargo holds bulk flow gate, basket gate & non-consolidated feeder

Our detail pages illustrated many safety aspects of Bulk carrier

Home page |||Bulk carrier types ||| Handling of bulk coal |||Cargo planning ||| Carriage of grain |||Risk of iron ores |||Self unloading bulk carriers |||Care of cargo & vessel |||Cargoes that may liquefy |||Suitability of ships |||Terminal guideline |||Hold cleaning |||Cargo cranes |||Ballast handling procedure |||Bulk carrier safety |||Fire fighting systems |||Bulk carrier General arrangement

Related information

-

Self unloader components

-

Function of loop & bucket belt elevators

-

Self unloaders various cargo handling gears

-

Dealing with self unloaders stalled lift belt

-

Conveyor belt construction & troubleshoot guide

-

Conveyor belt installation guide

-

Conveyor belt repair & maintenence guide

-

Safe working practice onboard self unloading bulk carriers

-

Preventing conveyor belt fire onboard self unloading bulk carriers

-

Cargo work safety precautions

-

Various bulk cargoes - free flow ability

-

Various bulk cargoes & dealing with cargo hang ups

-

Navigation in Ice & safety precautions

-

Dust suppression procedure & environment protection

-

Preparations for cargo planning, handling & stowage

-

Maintaining safe stability onboard self-unloading bulk carriers

-

Procedure for bulk cargo handling prior to and during loading

-

Loading operations - voyage orders, draft restrictions, various grades and rates

-

Loading sequence and other related considerations

-

Preparations for discharging & related guideline

-

self-unloaders-discharging-operation

-

Safety precautions for boom operation

-

Directing gate operation, gate problems & crew duties

-

Cargo holds/ tunnels cleaning, maintenance and check items

-

Procedure for transporting coal on self- unloading bulk carriers

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

It is vital to reduce the likelihood of over-stressing the ship's structure and also complying with all essential safety measures for a safe passage at sea. Our detail pages contain various bulk carrier related topics that might be useful for people working on board and those who working ashore in the terminal. For any remarks please Contact us

Copyright © 2010 bulkcarrierguide.com All rights reserved.

Although every effort have been taken to improve the accuracy of content provided the publisher of this website cannot take responsibility for errors. Disclaimer Privacy policy Home page