The general-purpose bulk carrier, in which usually the central hold section only is used for cargo. The partitioned tanks which surround it are used for ballast purposes either on ballast voyages, or in the case of the saddle tanks, to raise the ship's center of gravity when a low density cargo is carried. Some of the double-bottom tanks may be used for fuel oil and fresh water.

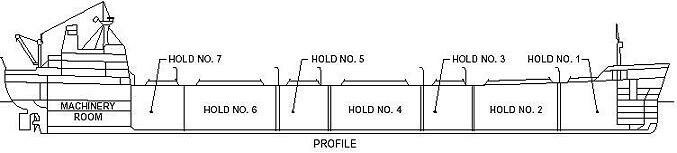

Fig :Profile of a typical bulk carrier

The saddle tanks also serve to shape the upper region of the cargo hold and trim the cargo. Large hatchways are a feature of bulk carriers, since they reduce cargo-handling time during loading and unloading.

Fig : A Bulk carrier on sea passage

Bulk carrier general arrangement and size range are similar to that of tankers, as shown in Figure . Single-purpose bulk carriers are generally designed as ore carriers, built to carry heavy cargoes stowing at 25 cubic feet per long ton or less, or dry bulk carriers, for grain and similar cargoes stowing at 45 to 50 cubic feet per ton.

Like tankers, the general arrangement of cargo spaces is dictated by the facts that the cargo is in the form of homogeneous particles of more or less uniform size, and can be transferred by blowers, conveyors, or grab buckets. Cargo spaces are divided into holds to meet structural and subdivision requirements, to restrain cargo movements and resulting upsetting moments, to permit the carrying of different cargoes simultaneously, and to provide for ballasting. Machinery is invariably aft, and the nonperishable nature of the cargoes leads to speeds in the 12- to 16-knot range, with attendant full hull forms.

Relatively small volumes of dense ores and similar cargoes will settle a ship to her summer load line. Holds on ore carriers are therefore quite small, bounded by broad wing tanks and deep double bottoms. The double bottom and longitudinal bulkheads are of heavy construction to carry the heavy ore load.

The narrow hold breadth limits transverse weight shifts and the depth of the double bottom is sufficient to keep the center of gravity of the ore high enough to prevent stiff rolling in a seaway. Large volume wing tanks are used for ballast.

Fig : Cargo hold construction of a typical bulk carrier

Designed for low-density cargoes, dry bulk carriers require much greater hold volume than ore carriers, and therefore have much shallower inner bottoms .

In some designs the topside tanks are omitted or fitted with bolted plates in the sloping plating facing the hold. When very light cargoes are carried, the plates are removed and the tanks are filled along with the hold; the cargo in the tanks feeds into the hold by gravity when discharging. Larger carriers are sometimes built with an inner side shell, which eases hold cleaning and provides additional ballast space.

Shallow double-bottom bulk carriers are sometimes designed to carry high-density cargo, by arranging them with alternate long and short holds. High-density cargo is loaded only in alternate holds to keep the center of gravity high enough to prevent excessive metacentric height.

The double-bottom structure under the holds intended for heavy cargo is augmented. The alternating cargo distribution causes high vertical shear near the bounding bulkheads, which may require increased shell scantlings.

With the increase in industrial demand for raw materials paralleling that for petroleum, the design of bulk carriers, like tankers, also evolved to include larger hulls. Bulk carrier deadweights range from quite small to over 200,000 tons.

In order to increase the proportion of payload operation above the 50-percent level typical of most straight bulk carriers (for tankers or dry bulk carriers operating between specific ports, cargo is often carried on only one leg of the journey), a trend toward combination carriers began about 1950. At first, these were dual purpose ships (ore/oil, bulk/oil) which carried different cargos on separate legs of a voyage cycle consisting of two or more legs. This development has evolved into combination carriers known as ore/bulk/oil ships (OBO). Despite differences, bulk carriers of all types have certain features in common:

i) Single cargo deck, without tween decks.

ii) Machinery aft of cargo spaces so shaft tunnel does not interfere with discharging gear.

iii) Large ballast capacity.

iv) Double bottoms under bulk cargo holds.

To facilitate rapid cargo discharge and minimize cleaning requirements, holds are designed with a minimum of internal obstructions that might catch and hold cargo. Bulkhead stiffening is attained by the use of corrugated plate rather than welded stiffeners. Hold cross section, is arranged so that cargo is self-trimming and self-loading:

i) Cargo will flow outwards from the point of discharge of bucket grabs or gravity chutes to fill the entire cargo space with a minimum of hand trimming.

Bulk carrier subdivision

ii) The narrowing width at the top of the hold limits transverse cargo shifts when the hold is not completely filled.

iii) During discharge, remaining cargo will flow to a fairly small area where it can be picked up by the discharging equipment.

Holds of different lengths may be distributed throughout the length of the ship for flexibility in cargo distribution; cargoes of varying densities can be distributed so as to keep the longitudinal bending moment within acceptable limits.

Except for equipment to open or remove hatch covers, most bulk carriers are without cargo gear. Cargo is loaded by gravity chutes or derrick grabs and discharged by grabs, conveyor systems, or in the case of grain and similar light cargo, by suction.

Some bulk carriers are built as self unloaders, either by the provision of derrick grabs, or by trimming the cargo spaces to belt conveyers running under the holds to a bucket conveyer which transfers the cargo to another belt conveyor on a long unloading boom. Conveyor type self-unloaders are fairly common on the Great Lakes . Combination carriers are fitted with cargo pumps and piping systems for discharging oil cargoes.

Related information on ships structural arrangements:

Mechanical steel hatch covers arrangement and watertight integrity onboard a bulk carrier

Ships structural problem because of corrosion & metal fatigues - related countermeasures

Classification Society Establishes Design Standards For Bulk Carriers

Hatch cover maintenance program

Corrosion prevention methods for bulk carrier

Maintenance procedure for mechanical steel hatch covers

Steel hatch cover maintaining watertightness - Classification society guideline

Structural standards & strengthening of bulk carriers