Home ||| Bulk Cargo ||| Planning ||| Care ||| Safety||| Self unloaders

Ventilation methods for bulk cargo against ship sweat or cargo sweat

Fig: Cargo sweat example

Many cargo claims arise due to lack of ventilation of the cargo, particularly agricultural products. A common procedure for ventilating hatches at sea is to `crack' them open.

Considerable care must be taken during this procedure as the ships hatch tops are not designed to be opened during any rolling motion. When such hatches are opened they must not be left in the jacked up position, but should be lowered onto the compression bars and locked into position.

Under no circumstances should the hatches be left open at night while on passage. A lack of, or improper, ventilation can lead to condensation (also known as sweating), which causes cargo deterioration. There are two types of sweat:

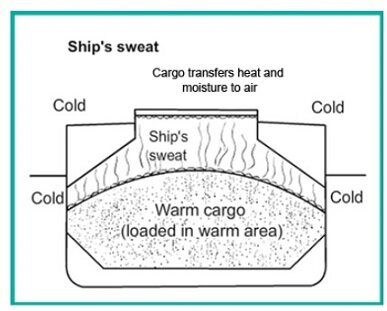

Cargo sweat

Condensation occurs on the surface of the cargo as warm, moist air enters the cargo hold containing a cold cargo. For example, if a cargo of steel is loaded in winter in the UK for discharge in Singapore, the temperature of the cargo will be low. If warm moist air is later introduced in the cargo hold, condensation takes place as soon as it comes into contact with cold cargo. To avoid the possibility of cargo sweat, all ventilators should be closed and no ventilation carried out. However, if the moisture content of the cargo is high, extraction of the moist air from within the cargo holds may be required.

Fig: Ship sweat example

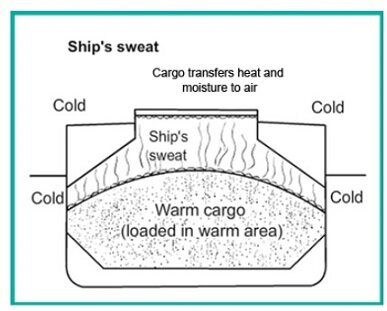

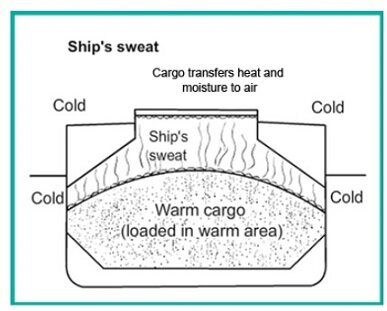

Ship sweat

This results when condensation occurs on the ship's structure as the ship becomes colder moving from a hot to a cold climate. The warm moist air within the cargo compartment condenses as it comes into contact with the cold structure of the vessel. For ship sweat to occur, the dew point in the cargo hold must exceed the temperature of the ship's structure. To eliminate ship sweat the cargo should be ventilated if the vessel is moving from a warm to a cold climate. Cargoes can be:

Hygroscopic : mainly agricultural products containing natural moisture. They may absorb, retain or release moisture, depending upon the surrounding atmosphere. Examples include grains. On a voyage from cold to hot region these type of cargo need no ventilation and from hot to cold region surface ventilation needed.

Non-Hygroscopic : solid cargoes. However, these cargoes are very likely to be damaged by cargo sweating. To avoid cargo damage no ventilation required

Air is said to be saturated if it can no longer absorb any moisture. If it is then cooled it will start to cause condensation. The temperature this occurs at is known as the dew point temperature.

To determine the amount of moisture in the air (the relative humidity), a wet and dry bulb thermometer is used in an instrument known as a `hygrometer'. It is important to ensure a flow of air across the two thermometers in a hygrometer to obtain correct readings. In a cargo hold where there is no air flow, a whirling hygrometer is used to measure the two temperatures. A table is then used to find the relative humidity at the time of observation. If proper ventilation procedures are not followed moisture damage is likely. Any shipper's instructions should be complied with and the following factors considered:

- Ensure that the shipper's declaration contains sufficient information about the cargo, particularly moisture content, TML and ventilation requirements, particularly if the commodity is not normally carried or the areas of trade are uncommon

-

- claims for moisture damage to cargo can only be defended if supported by properly maintained documentation. It is critical that records of hold temperatures, humidity and durations of ventilation are maintained

-

- the dew point temperature of the cargo hold and outside air should be compared. If the outside dew point temperature is lower or equal to that within the cargo hold, then ventilation should be continued. Since measurement of temperature in a cargo hold filled with bulk cargo may not always be possible, a comparison should be made between the temperature of cargo at the time of loading and the outside temperature. If the dry bulb temperature of the outside air is 3 degrees or more higher than the cargo temperature, continue ventilation

-

- ventilation not only serves to control sweating, it can control the gases or odours emitted from cargo

- if seawater spray or rain enters the cargo holds, all ventilation should be stopped and times noted until conditions change to allow resumption of ventilation

-

- ventilation should be continued even at night if required

-

- if circumstances allow there should be regular inspection of the cargo space for any signs of condensation, eg on the underside of the hatch access covers. If condensation is found, ventilation should be continued

-

- a record of cargo hold temperature and ventilation should be kept.

Fig: Modern handymax bulkcarrier

Low inherent moisture content cargoes

For a hold loaded exclusively with cargoes containing no inherent moisture the only moisture available for condensation as ship's sweat will be the comparatively minute amount in the small mass of the volume of air within the hold. It is therefore highly unlikely that ship's sweat formation sufficient to drip back onto a cargo will ever occur under any voyage circumstances; the safest option for these types of cargoes is not to ventilate.

High moisture content cargoes

Cargoes in the high moisture content category are usually hygroscopic - that is they can absorb or release moisture into their immediate surrounding atmosphere depending on the moisture content of the cargo and the concentration of moisture in the immediate surrounding atmosphere. Thus, the relative humidity and also the temperature of the atmosphere in a hold containing these cargoes is principally controlled by the moisture content and temperature of the cargo as loaded. (A proviso here is that these latter parameters are numerically suitably low for the cargo to be inherently stable, hence precluding the possibility of any significant self-heating in transit due to microbiological activity).

It will be appreciated that the substantial amounts of inherent moisture even in stable cargoes of this type provide an enormous "reservoir" of moisture for potential release into the associated atmosphere within a ship's hold. This applies to a much lesser extent to cargoes in the low moisture category where the risk of any substantial ship's sweat formation is therefore correspondingly much lower. Usually, however, the same principles of ventilation apply to cargoes in the high and low moisture categories, although in the latter category there can be some exceptions.

These include some organic and inorganic fertilisers in bulk or in permeable packaging where, for special reasons which are outside the scope of discussion in this article, the normal criteria of ventilation may not apply and it may be appropriate to seek specialist advice.

Maintaining accurate records when ventilation not possible

The need to ventilate especially high moisture content cargoes (stowage and sea conditions permitting), whenever external temperatures are significantly lower than cargo temperatures - and then not only in daytime but importantly also at night .

If ventilation is impossible because of prevailing sea condition, it is of utmost importance that all relevant aspects of weather and sea conditions are fully logged. The only other circumstance where surface ventilation, when desirable, may not be feasible is when stowage considerations in relation to the design of a ship's ventilation system preclude effective ventilation. For instance, for cargoes of grain and some allied products in bulk, it is essential for stability reasons that at least some holds are fully loaded to the tops of hatch coamings, which may render surface ventilation difficult or impossible.

In all other circumstances the text book rule concerning ventilation of the most hygroscopic cargoes containing significant amounts of moisture is to ventilate when the dew point of the external atmosphere is lower than the dew point of the atmosphere in association with a cargo within a ship's hold and, conversely, not to ventilate when the relative situation as regards external and internal atmosphere dew points is reversed.

In theory this rule is entirely correct, since dew points of different atmospheres have a directly proportional relationship, to the absolute amounts of moisture which they contain.

Related information :

Risk of ship sweat and how to minimise

Ventilation requirement for various cargo

Cargo sweat and ships sweat & recommended ventilation methods

Causes of bulk carrier hull damage and failure in operation

Additional cargo documents required for bulk cargo loading

Top articles

- Navigation in Ice & safety precautions

- Ships Confined area safe practice

- Handling water ingress problems in bulk carrier, investigation and countermeasures

- Survival and safety procedure for bulk carriers

- Monitoring hull stresses during rough sea conditions

- Precautions against bulk cargo which may liquefy

- Cargo damage survey guideline

Our detail pages illustrated many safety aspects of Bulk carrier

Home page |||Bulk carrier types ||| Handling of bulk coal |||Cargo planning ||| Carriage of grain |||Risk of iron ores |||Self unloading bulk carriers |||Care of cargo & vessel |||Cargoes that may liquefy |||Suitability of ships |||Terminal guideline |||Hold cleaning |||Cargo cranes |||Ballast handling procedure |||Bulk carrier safety |||Fire fighting systems |||Bulk carrier General arrangement

Operation of sea going bulk carriers involved numerous hazards . Careful planning and exercising due caution for all critical shipboard matters are important . This site is a quick reference to international shipping community with guidance and information on the loading and discharging of modern bulk carriers so as to remain within the limitations as specified by the classification society.

It is vital to reduce the likelihood of over-stressing the ship's structure and also complying with all essential safety measures for a safe passage at sea. Our detail pages contain various bulk carrier related topics that might be useful for people working on board and those who working ashore in the terminal. For any remarks please Contact us

Copyright © 2010 bulkcarrierguide.com All rights reserved.

Although every effort have been taken to improve the accuracy of content provided the publisher of this website cannot take responsibility for errors. Disclaimer Privacy policy Home page